Key Advantages & Features

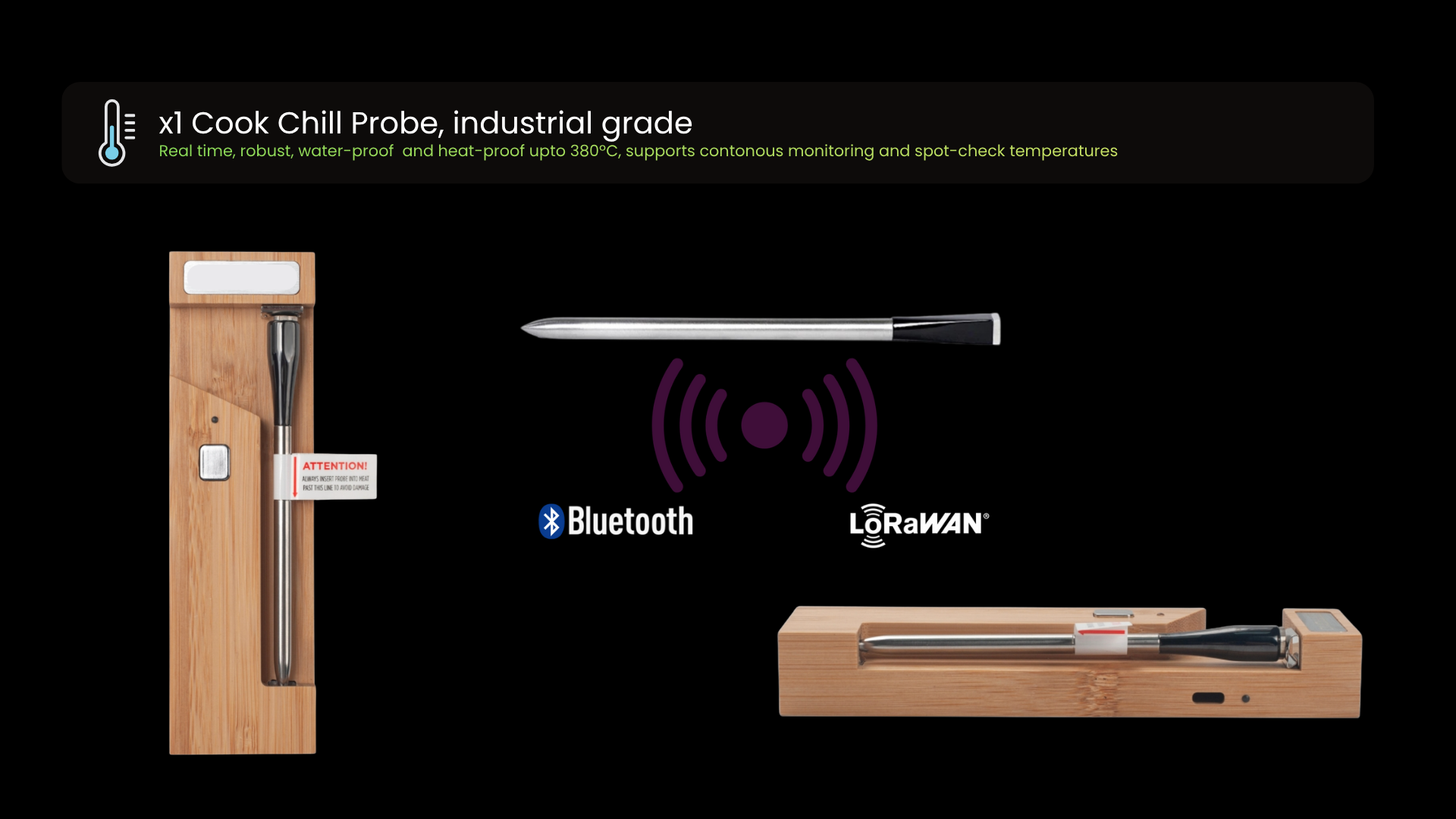

Dual Communication: Bluetooth + LoRaWAN

Bluetooth Mode:

Instant, direct connection to the DIGE Android App

Integrated with CAMPRO (Camera + Probe) for rapid checkpoint data capture, annotating photos, and linking readings to tasks

Ideal for handheld or mobile use

LoRaWAN Mode:

Long-range wireless connectivity for continuous CookChill monitoring

Transmits through production kitchens, cold rooms, and blast chillers

Works with MultiTech or any DIG-compatible LoRaWAN gateway

This hybrid technology makes the probe suitable for both portable spot checks and end-to-end batch temperature tracking.

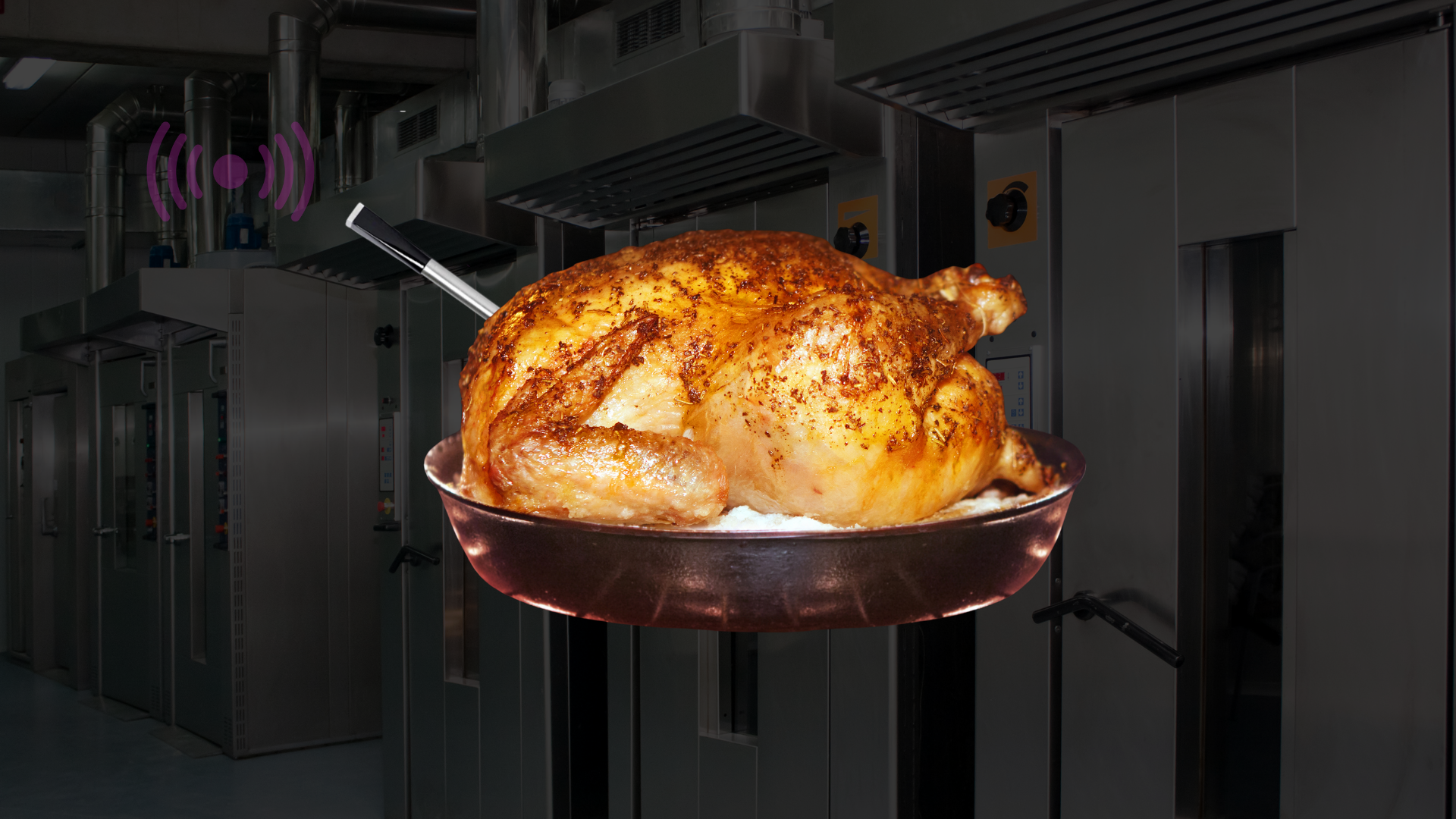

Heatproof & Waterproof Cooking Probe

Designed to remain inserted in the product throughout cooking and chilling

Resistant to:

High heat during roasting, boiling, sous-vide, steaming

Rapid temperature drops in blast chillers

Full wash-down environments and wet processing areas

Ensures continuous, accurate tracking of the food’s internal temperature without manual re-insertion.

Ideal for Cook–Chill Operations

The CookChill Probe is engineered specifically for operations where:

Food is cooked to a required kill-step temperature

Immediately chilled rapidly within regulated timeframes (often <90 min)

Continuous temperature records are required for HACCP, ISO 22000, and national food safety compliance

The probe captures the entire temperature curve automatically, enabling full traceability of each batch.

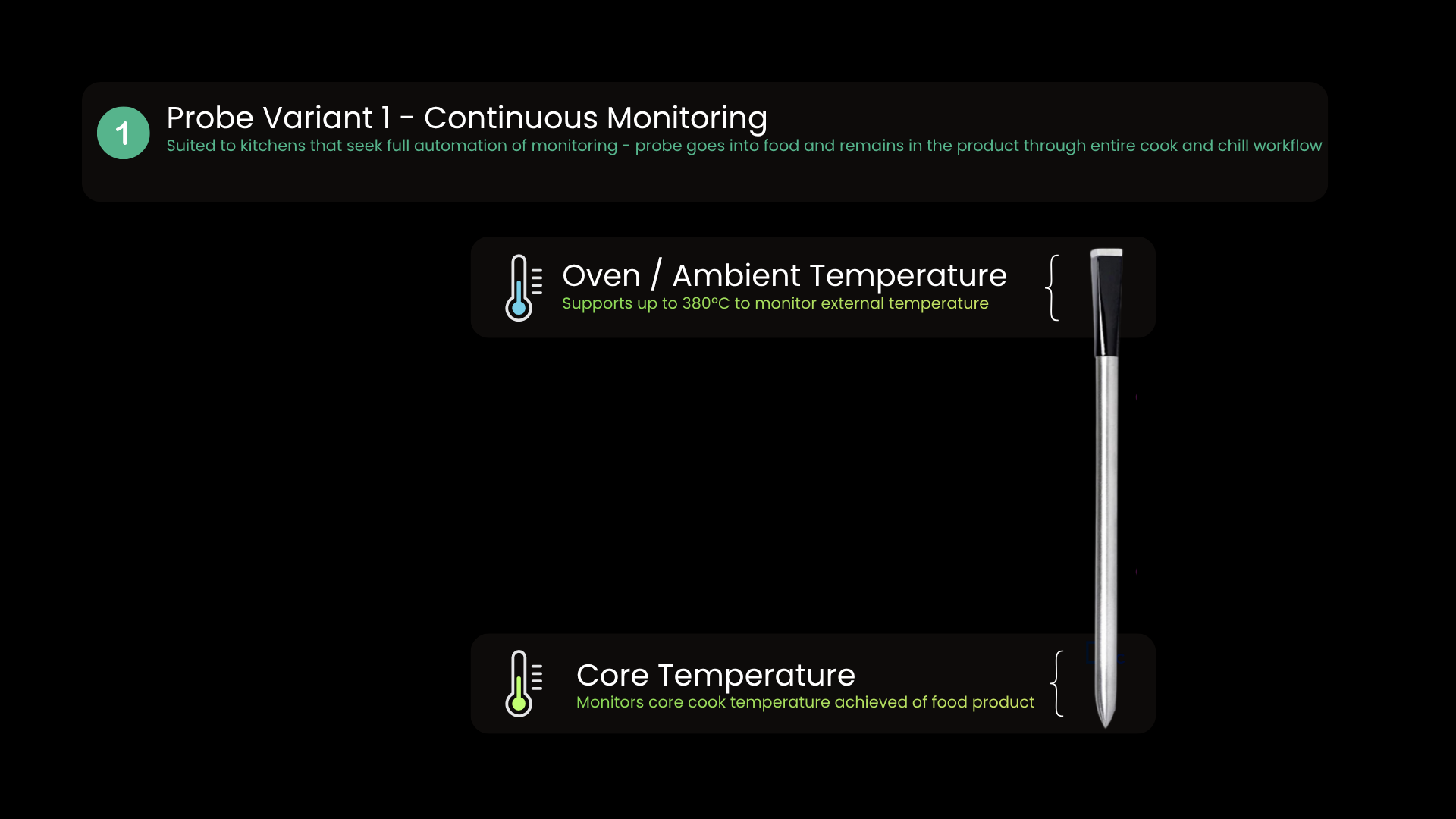

Two Modes of Use

1. Continuous Monitoring Mode (LoRaWAN)

Used when the probe stays in the product for the entire CookChill cycle. Requires:

A LoRaWAN Gateway (e.g., MultiTech MT-CAP or equivalent) for continuous data transmission.

Perfect for:

Food manufacturing plants

Central kitchens

Blast chilling processes

Batch verification

HACCP CookChill checkpoints

2. Handheld Pen-Type Thermometer Mode (Bluetooth Only)

Used for spot checks, audits, and regular checkpoints. Does NOT require a gateway. Directly connects to:

Didge Android App

CamPro workflow (photo + measurement + corrective action)

This flexibility makes the CookChill Probe a single device suitable for multiple roles.

Cradle, Charging Base & Accessories Included

Each CookChill Probe ships with:

Charging cradle (dock)

Charging port / USB-C / proprietary connector (model dependent)

AC charging adapter

Pre-configured digital profile

Pre-charged battery

The cradle also serves as an organised, hygienic storage base.

Fully Pre-Configured for the DIG Platform

Before shipping, we configure the unit to:

Pair with your DIG instance

Sync with your workflow checkpoints (especially CookChill)

Be inspection-ready upon delivery

When you receive it:

Turn it on

Place/use the probe

Start recording instantly

No pairing. No provisioning. No firmware steps.

What’s Included in the Box

CookChill Probe (Drogano DMT01 platform)

Heatproof, waterproof stainless steel probe

Charging cradle

Charging cable + AC adapter

Fully configured DIG Platform profile

Quick start activation card

Optional: multi-tech LoRaWAN gateway (if part of your package)

Technical Specifications

Probe

Material: High-grade stainless steel

Waterproof & heatproof

Suitable for high-heat and rapid chill cycles

Designed for immersion, oven use, steamers, blast chillers, and boiling pots

Communication

Bluetooth Low Energy (BLE)

For handheld readings

Direct to Didge App + CamPro

LoRaWAN

Long-range, low-power monitoring

Compatible with MultiTech and standard LoRaWAN gateways

Supports continuous CookChill cycle logging

Charging & Power

Charging cradle (dock)

AC adapter included

Rechargeable battery

Multi-day operating lifespan depending on reporting mode

Auto-wake and power-saving features in Bluetooth mode

Data Handling

Real-time transmission via LoRaWAN

Instant readings via Bluetooth

Continuous CookChill batch data logging

Encrypted communication

History securely stored in DIG Platform for audits

Compliance & Food Safety

The CookChill Probe supports compliance with:

HACCP

ISO 22000 / 22002

National food safety regulations requiring validated cook and rapid-chill monitoring

Full temperature traceability

Batch-level audit trails

Verification of kill-step and cooling curves

It is engineered for manufacturers who must demonstrate safe processing temperatures from heat to chill.

Use Cases

Cook–Chill manufacturing

Bulk food production

Centralised kitchens

Blast chilling verification

Sous-vide cooking + cooling

Batch processing

Regulatory audit documentation

High-risk food categories (meat, poultry, seafood, sauces)

Installation & Activation

Unbox the probe & cradle

Place the cradle in a convenient location and plug in the charger

Activate via the DIG Platform (pre-provisioned)

For CookChill continuous monitoring: probe stays in the food; data goes via LoRaWAN Gateway

For handheld use: open DIGE App → Bluetooth connect → take readings

Begin using immediately